Casa prefabricada-2

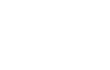

• Wall &Roof: EPS/Rockwool Sandwich thermal insulation panel

• Door: Steel Open Entrance door

• Window: Aluminum alloy sliding door

• Floor: PVC or wooden floor

• Ceiling: Sandwich thermal insulation ceiling

• FOB Qingdao: USD 900~1000/Ton

• MOQ: 500 SQM

• Factory Capacity: 1500-2000 tons/month

• Leading time: 20 ~45 days

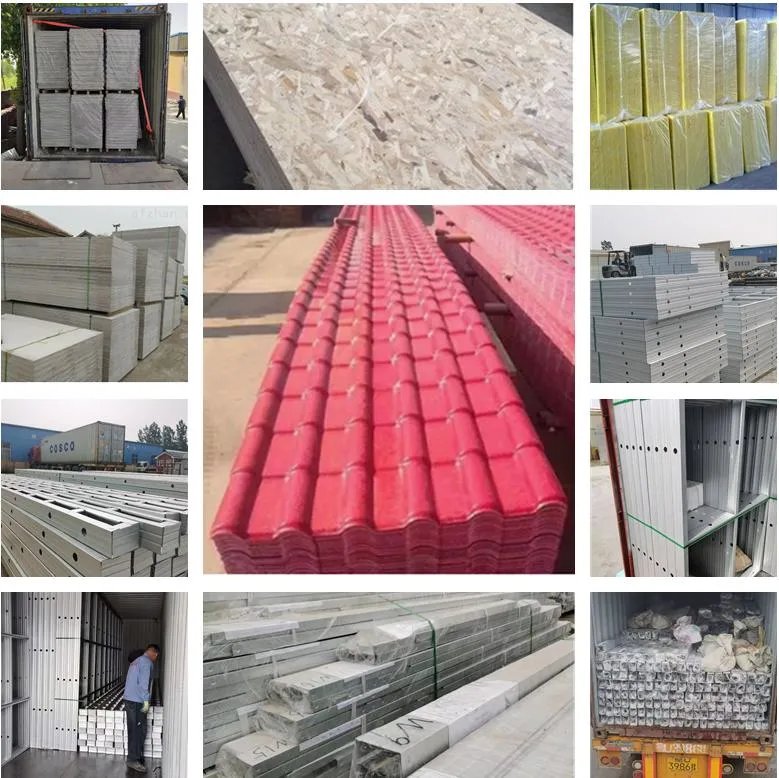

• Packing: Steel pallet package for container delivery

DETALLES

Fast installation prefab modular house container house tiny house

◆ Product Description

Tamaño | como petición de los clientes |

Color | de acuerdo a la solicitud de los clientes |

Cargando | Contenedores 40'HQ |

Estructura | Base de acero: Q235, galvanizado en caliente. Acero recubierto de energía de 2 mm como viga principal y acero de 1,5 mm como segunda viga |

Columna: acero de 3 mm, Q235, galvanizado en caliente, recubierto de energía | |

Esquina de acero con orificio: Q235, galvanizado en caliente, recubierto de energía | |

Sistema de techo: Q235, galvanizado en caliente. Acero recubierto de energía de 3 mm como viga principal y acero de 1,5 mm como segunda viga. | |

panel de pared | Panel sándwich de lana de vidrio de 50 mm/EPS |

Techo | chapa de acero de color como chapa de techo+aislamiento de lana de vidrio de 40 mm+techo |

Piso | Panel de MgO de 16 mm, con lámina de vinilo de 2 mm |

Ventana | Ventana corredera de aluminio |

Tamaño: según lo solicitado | |

Puerta | Puerta de acero, con cerradura con tirador y llaves. |

Tamaño externo: según lo solicitado | |

Sistema eléctrico | 1 distribución eléctrica, 2 enchufes industriales, 2 luces, 2 interruptores, 3 tomas (con toma A/C), |

cable eléctrico (220V/50Hz) | |

La temperatura | temperatura adecuada.-50°C~+50°C |

Otros | Los muebles y electrodomésticos se fabrican a la medida de sus necesidades (costo adicional) |

Carga de piso | 0.5KN/metro cuadrado |

Carga de techo | 1.5KN/metro cuadrado |

Resistencia al viento | Grado 11 (velocidad del viento≤111,5 km/h) |

◆ Advantages

1.Earthquake resistance: It can withstand 9 rare earthquakes and is suitable for areas with seismic intensity above 8

2.Wind resistance: resistant to 70m/s hurricane, Max. 280km/H

3.Durability: The main structure can last for more than 50 years

4.Fire resistance: refractory time of up to 1~4 hours according to different designs

5.Sound insulation: the sound insulation of the external wall can reach 75dB, and the inner wall can reach 55dB.

6.Heat Insulation: The thermal resistance of 200mm thick composite wall can reach 3.2m2K/W, which is 11 times that of traditional buildings of the same thickness.

7.Environmental protection: more than 90% of steel structure materials can be recycled, and most other supporting materials can be recycled.

8.Energy-saving: using new materials for heat preservation and heat insulation, the energy required for heating and cooling is 65% more energy-efficient than traditional buildings.

9.Housing rate: Light steel integrated housing increases the practical area by about 12% compared with traditional buildings

10Construction period: assembly and standardization of light steel structure houses is simple and fast, saving 2/3 construction period compared with traditional structure

◆ Design capability

By using Auto CAD, PKPM,3DMAX,SAP2000,Tekla, Vertex etc. We can design different houses according to customes requirement.

◆ Product Parameters

1. EPS foam board/ Fiberglass sandwich panel as wall or roof cladding, is a thermal insualtion sandwich panel which made of 2 pcs steel color sheet with EPS foam or Fiberglass insulation at middle, with features light weight, easy installation, low cost, strong low ability, sound proofing, thermal insulaiton, heating insulation and good moisture resistant, etc.

2. Thermal Insulation fiberglass mineral material

a. Class A1 non-combustible material

b. No odor, environmentally friendly and non-toxic

c. Thermal conductivity ≤0.03W/cm.k

d. heat resistance ≥700 degrees

e. Porous structure, good recovery, not afraid of any shock

3. AL-ZN Cold Form C profile

Light weight, easy for installation, Best Antirusting material as Grade G550, Galvalume treatment, AZ275gram/SQM, Thickness 1.0mm long term durability. Warranty min. 50 years.

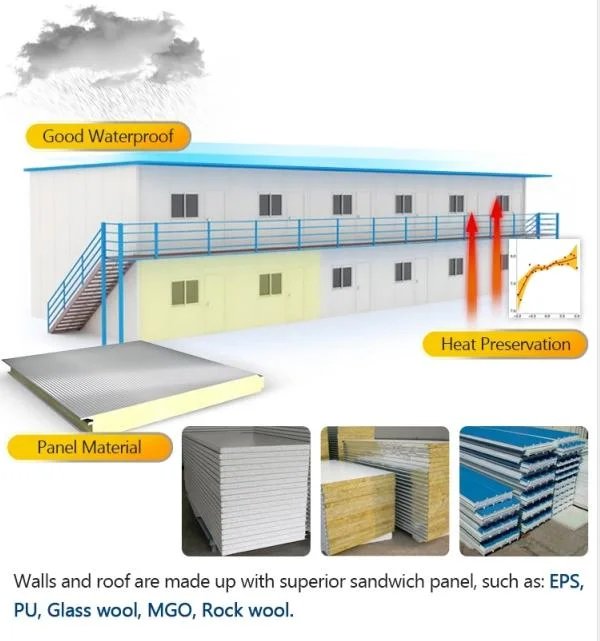

◆ Factory Overview

Factory Established in 2008

Company Area more than 40,000 SQM

Workshop More than 25,000 SQM

Production Line:

2 Sets CNC Flame Cutting Machines

5 Lines for builtup H profiles

3 Lines for C Girt or Z purlins

3 Lines for Corrugated Wall or Roof Metal Sheet

3 Lines for Sandwich Panel Sheet---Wall, Roof, EPS, Glasswool, Rockwool, XPS, etc

1 Set Shot Blasting Machine for Painting Pretreatment.

◆ Quality Control

1. QC processing:

1. Every 3 months meeting for Quality Audit to solve the weakness during processing and procedures

2. Every 6 months meeting for employee training.

3. Producing as to the International Steel Structure Standard with ISO 9001 Quality Control System and European CE Standard both.

4. Each project, every 6 months, connecting with clients for feedback and complaints, then improve the quality control actions.

5. Quality inspection report for every process during production. Ensure 100% good quality products.

◆ Company Certificates:

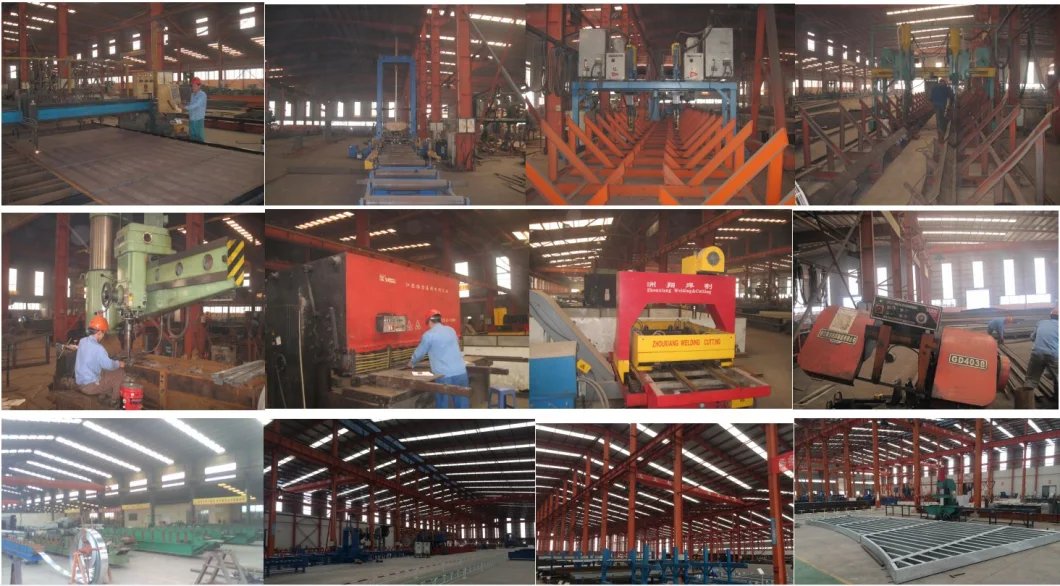

◆ Guide Installation Processing

◆ Packaging & Shipping

◆ After Sales Service

We service customers more than 40 countries all over the world. We establish good business relationship with clients in Poland, Luxemburg, France, Germany, UK, Austria, Angola, South Africa, Egypt, Reunion Island, Maurituis, UAE, Dubai, Russia, India, Singapore, Thailand, Australia, New Zealand, Indonesia, Phillipines, Fiji, Sri Lanka, Mexico, USA, Canada, St. Lucia, Trinidada and Tobago, ect.

◆ Our Customers

◆ FAQ:

1.Q: Do you have the Engineer team to design the steel villa for me?

A: Absolutely! We are able to provide you with not only construction scheme , but landscape design! One-stop service is our outstanding superiority with no doubt.

2.Q: What should I provide to build a steel villa?

A: if you have the plan layout, it will be easier for us.

If not, pls inform the wind speed, snow load, building dimension W X L X H, Rainfall capacity, Earthquake scales, etc. then we will design for you as request.

3.Q: What is the processing for placing order of villa house?

A: Firstly, the designing scheme should be accepted. Then, the kinds of building materials should be confirmed since different types and qualities make various prices. After that, we will send you a detailed quotation. As cost agreed, then you arrange the down payment for production, after produced ready, we arrange the delivery, then you pay the balance, after that, we will send the guide installation drawings to you help for erection the house.

4.Q: How Long does it take to build a light steel prefab house?

A: It depends on the size of the house. Generally, one 50 square meter house five workers 1-3days finished installation, save manpower and time

5.Q: Is it difficult to build a steel villa ?

A: Totally not, you can build the house independently according to the construction drawings as long as you know how to use an electric tool.

6.Q: Does this kind of house can only be used in residential building?

A: Absolutely not. It can be used in all kinds of buildings, such as hotel, office, school, entertainment club, light industrial workshop, ect.

7.Q: Is steel villa stable?

A: Set your hearts at rest! You are completely safe living in light steel prefab house even if there are hurricanes of 200km/h and 9-grade earthquake outside.

8.Q: what are the advantages of steel villa comparing to the traditional building?

A: Better isolation of sound and heat,Better fireproof and anti-seismic,Wind resistance,Time and labor saving,More usable area,Excellent

CONSULTA GRATIS AHORA

Si tiene alguna duda o necesidad sobre el producto, por favor rellene el siguiente formulario y nos pondremos en contacto con usted lo antes posible.